Mica Dam

This project began in 2010 and was completed in 2014 at a hydroelectric dam in Mica Creek, BC. The concept for this machine literally started as a sketch on a napkin over lunch with the manufacturer of the power bus.

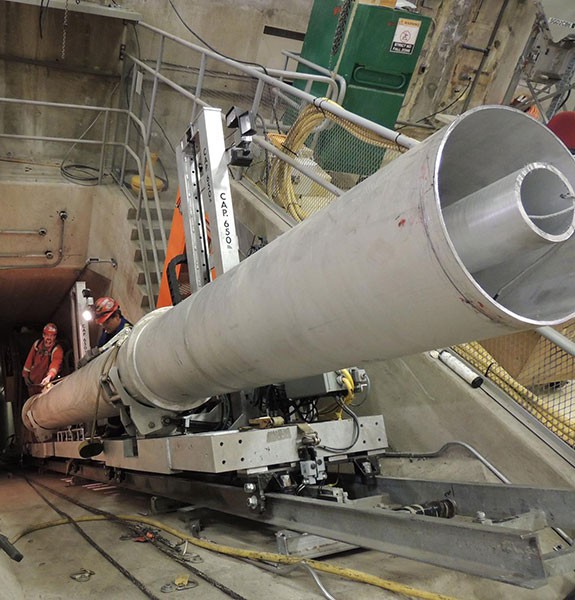

This system was designed to transport and install 1,300-lb, 35 ft. long sections of power bus in two different lead shafts at the dam. This power bus brings the generated power from a transformer gallery, up the lead shaft to where it gets distributed to the high tension power lines. Each shaft is 8 ft. wide by 10 ft. tall with a maximum length of 900 ft. One shaft is at a 45 degree angle the other is at a 54 degree angle.

Our job was to design and build a system that was capable of operating in both shafts by climbing a rail system carrying the bus section and 3 men up and down the shaft. The operators used the system's claw mechanisms to remotely lift and manipulate each bus section onto brackets mounted along one wall of the shaft.

These photos show our system on the day of final testing before the machine was commissioned for use. We designed, built, and tested this system having never been to the job site 3,000 miles away. Our first visit to the site was on the first day the system was to be installed in the first lead shaft.

The Mica Dam project has been completed. Our system safely made over 300 trips carrying men and material up and down the lead shafts.